If you intend to market products more quickly, you’ll need to use rapid tooling to produce parts that are available for testing. There are several innovations that have been developed in the processing industry recently; among them are the different prototyping techniques that play a crucial role In the development stage. That’s all what entails rapid prototyping.

What is Rapid Tooling?

Rapid tooling refers to the process of making prototypes in a short period. It all started in the early 1990’s when engineers used the plastic injection molding process to create molds quickly instead in longer periods.

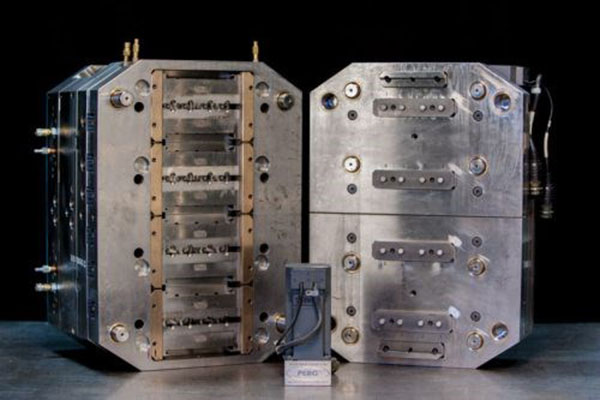

Parts made using through the rapid tooling process is a perfect way of evaluating and testing prototypes and make some parts before going into the full production stage. Rapid tooling builds inserts like the cavity, side actions, and core of these parts. It depends on the rapid tooling method employed; many parts can be produced using several cycles of one mold.

There are several rapid tooling methods that you can choose from; each of these techniques comes with its own benefits. There are several factors that you must consider to enjoy the most rapid tooling benefits.

rapid tooling services*

The following are some factors you should consider when choosing your rapid tooling materials:

- Strong Mold

Your mold needs to be strong enough to enable it withstand the rapid tooling process. Molding machines clamps heated materials into your mold, meaning that it should withstand raid tooling injections.

- Smooth Mold

Aside from strength, the materials should be smooth to ensure that the plastic is injected cleanly; this is a critical characteristic since it’s required for all injections. Some processes in rapid tooling adds materials a layer at a time, making them rough. If this is the case, the finished product needs additional finishing to be used for prototyping.

How it Works

Rapid tooling is an injection molding process that comes with 3 components; machined mold, raw plastic, and the injection molding machine. The process involves melting raw plastic in the machine followed by injecting it to the mold. It’s then allowed to solidify and cool into the final part.

Rapid Tooling Applications

The applications of rapid tooling continue to change as time passes, this is because of the procedures development. The following are some of the rapid tooling applications:

- Making molds, these molds can be non-metallic or metallic

- Rapid tooling works excellently for high or low volume manufacturing and prototyping. It’s used to produce thousands of parts and it’s well-known in production of medical syringes, bottle caps, and Lego bricks

- Making EDM electrodes and marking stamps

- Producing hybrid patterns used in casting

- Production of splintering tools

- Making cores and casting shapes, the latest technology used in cores and casting shapes is the SLS rapid tooling application

There are several reasons why you need to consider using rapid tooling. It’s an affordable, effective, and quick way that enables you to market your parts quickly. Cost effectiveness is the most important since it enables you to do market testing, which is ideal for low volume productions.