Do you have a project that requires quick prototyping? The experts can provide customized help from the start of your industrialization process. The wax model is used to create metal prototypes using fast prototyping techniques. There are several options accessible to you; visit going-rapid to take advantage of our quick prototyping services.

Concerning fast prototyping

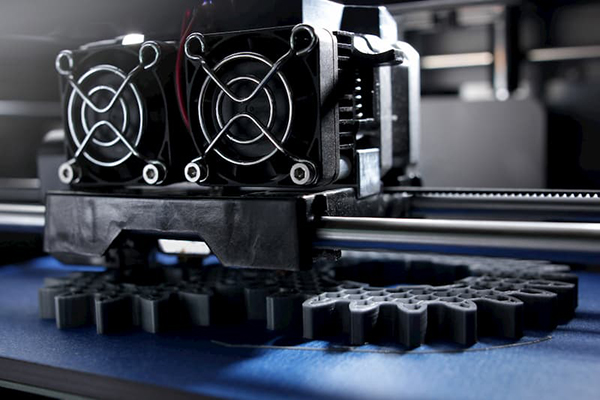

A 3D CAD (Computer-Aided Design) model is represented by the prototype. Rapid prototyping helps you swiftly develop a concept and test the significance of specific design decisions. Lower manufacturing costs can be achieved by optimizing the form of your product. For the production of your models, we create metal prototypes utilizing fast prototyping methods. The rapid prototyping techniques employed are 3D printing, PMMA binder jet printing, and even silicone mold.

These tools mainly enable you to do both technical and process validation for the lost wax casting process. Rapid prototyping incorporates three key concepts: time, cost, and form complexity.

3d printing machines*

Time:

Rapid prototyping aims to build models fast to shorten the time it takes to develop a product.

The cost:

Fast prototyping allows you to create prototypes without the need for expensive tools, and it ensures the final product’s performance.

Shape complexity:

Machines can create highly complex forms that are impossible to produce with traditional methods like milling.

Mock-ups and prototypes are two different forms of mock-ups.

The physical representation is required for two types of product design:

These are representations that allow you to view the object and representations that allow functions to be validated.

The model and prototype are present at every stage of product development:

Make a mockup or use a design template.

You may assess the aesthetics of the upcoming product using mockups or design templates. It may also be used to do art market research. You like to utilize low-cost materials.

Prototype in geometric form

The geometric prototype aims to ensure that the forms and proportions are consistent with the digital CAD model. You can make digital modifications or even physical model alterations during product development.

Prototype that works

The functional prototype allows for the validation of the product and the optimization of its assembly and working principles. The approval of this prototype allows the design of the tools to begin.

Prototype technology

Technological prototypes are made using materials that are compatible with the manufacturing process.

Quick-reference tools

Rapid tooling is the process of making tools or portions of tools quickly to create high-quality materials. Rapid tooling is used to make plastic injection molds, sand moulds for foundries, and press tools. Plastic injection molds can be made in a variety of ways.

Sintering of metals using lasers

Metal rapid prototyping 3D allows you to manufacture more quickly and at a lower cost. It’s a powder-based method that’s the most widely used metal 3D printing technology right now. A laser creates a two-dimensional pattern in a metal powder foundation, then applies a new layer of powder and repeats the process until the required shape is produced. This is a lengthy process, but the end product is still good in terms of strength and durability.