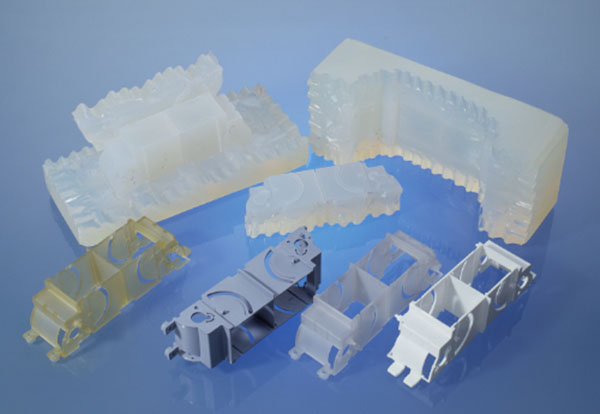

There are many of you who have heard about the vacuum casting of plastics but have yet to come up with a clear answer to the question of what it is and why it is needed. It consists of pouring polymers into silicone molds, which allows for the fast production of a huge number of plastic objects of virtually any complexity and size, ranging from little gears to massive instrument boxes, among other applications.

Note that vacuum casting in silicone molds in a small series is relatively expensive, but that as the volume and number of copies increase, the costs for the individual parts fall as well. Modern production processes make it feasible to manufacture things with virtually any texture or color in a very short amount of time, thanks to advancements in technology.

Technology for vacuum molding plastic in silicone molds.

The technology of casting silicone molds is most commonly employed for the casting of plastic products in small batches (up to 1000 pieces). In terms of cost and preparation time for manufacturing, this casting process provides a significant advantage over other methods of product development. The benefit is that liquid polyurethane is utilized for molding plastic products and is put into the mold at normal temperature, eliminating the requirement for high pressure. The mold is filled by placing it in a vacuum chamber, which eliminates the need for a labor-intensive metal mold.

vacuum casting parts*

These are the situations when you might need to use vacuum casting:

- Product casting in small series ranging from 1 to 1000 pieces.

- Production of test master models, product design development, and, if necessary, further modification for mass production

- Before the batch goes into serial production, samples are produced for client display.

- Product manufacturing for the certification process, which necessitates the creation of a sample comparable to the future series product.

- Meeting primary market awareness about the product until the metal mold is ready (it takes a few days to start pouring in silicone molds, as opposed to producing metal molding, which takes several months)

- Need to refurbish a damaged or broken part or a retired product that is already off the production line.

What should you look for in a vacuum casting service?

- Lookup for a company that will bring together certified specialists, designers, engineers, and programmers who are passionate about 3D technologies.

- Search for professionals who don’t just work with enthusiasm but also have a well-developed production foundation that allows you to put even the most audacious ideas into action.

- Service that has perfected the production technology to the finest detail, and manufactures lifelike figurines. Look for reviews, that is important.

- Companies that own their own equipment, are able to maintain their pricing for casting polyurethane products lower than those of other companies. So, lower pricing does not always mean worse quality.

- Good companies compute the cost of the service, which includes: cost, material, and production time in advance. The delivery to any place in the city that is convenient for you and payment in a way that is comfortable for you.