If you’re not sure if vacuum casting is among the cost-effective methods of making prototypes, this article will show you why it’s a good choice. Vacuum casting is also referred to as polyurethane or urethane casting. It was first innovated in 1960s and it has become one of the most popular prototyping techniques.

Vacuum casting refers to copy manufacturing methods that makes use of silicone mold. It’s an ideal prototyping process that works similarly to injection molding.

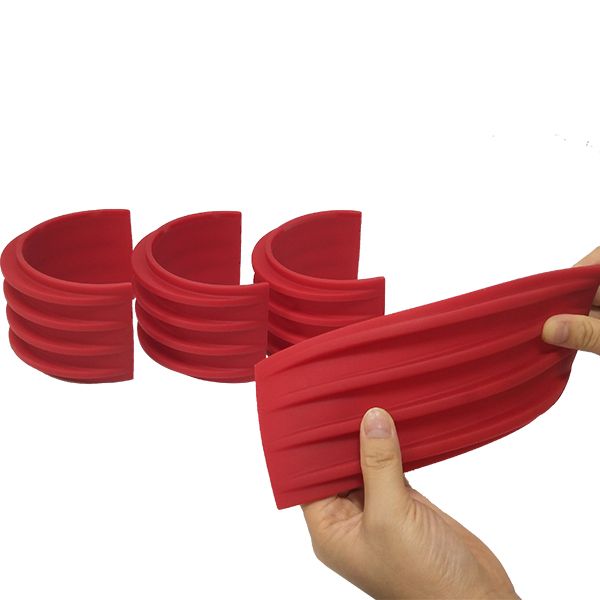

The technique is an effective and flexible method used for producing quality prototypes and final products in low volumes. It’s considerably quicker than conventional prototyping techniques. Vacuum casting uses silicone molds and casting resins which can be recycled for approximately 20 times; it results in perfect replicas of original patterns. These replicas are useful in several ways such as crowd funding campaigns, marketing, display models, product development, engineering testing, and functional testing.

Vacuum casting has been born by the fast technological advancement. It has become very popular between corporations, entrepreneurs, and manufacturers. Being one of the budget-friendly production methods for low volume productions, it ensures consistency and quality. However, vacuum casting isn’t limited to material options, the risk of continued flow, limited intolerance, etc.

customized ABS plastic vacuum casting products*

Why Choose Vacuum Casting

The following are some benefits of using vacuum casting:

- Fast production

Silicone mold used in vacuum casting can be used within a day. A single mold can produce approximately 30-50 parts in 20 days. Vacuum casting offers continuous production systems. Compared to 3D printing and CNC machining, it saves machine preparation time. Injection molding is similar to vacuum casting though it takes several weeks to manufacture aluminum mold. Simply put, this method saves a lot of time as compared to conventional prototyping methods.

- Cost Effectiveness

Silicone is cheaper than aluminum; aluminum is approximately 45% more expensive than silicone. To cut machining cuts when using CNC prototyping, it requires extra costs making it expensive and high labor costs. Vacuum casting is environmental friendly and replicates parts without wasting materials.

- Unmatched Material Stimulation

Materials are the key factors that make vacuum casting very popular; polyurethanes stimulate major material properties. Such properties include strength, minimal heat resistance, high flexibility, and high impact strength. These materials include rubber, ABS, and PMMA. Polyurethanes are needed to perform different properties of flexibility, smoothness, rigidity, etc. as per the owner’s final products’ requests.

- Surface Treatment

Vacuum casting process performs excellent surface finishes on the produced parts, depending on the client’s request. The cured silicone has comprehensive reduction in comparison to the original model. The surface treatment saves time and costs to the copies that follow.

- Consistency

Consistent function and appearance are favorable to market testing and research. Silicone molds produced by master models ensure replicated parts have similar features in terms of finishing, size, and shape, etc. Quick turn around and consistency are flexible to the customers’ references.

- Thin-wall Casting

Vacuum casting results in products that are light in weight and of higher technical advancements, which is essential in some specific conditions. Products that feature functional shells need thin walls to focus on the maximum effects. Products featuring complex internal structures rely on conduction in between any thin-wall parts. Vacuum casting produces parts that can be thin-wall and compact.